Automated Mouth Dissovled Souble Pet Breath Oral Care Strip Type Films Melting Disintegrating Making and Packing Machinery

Oral Film Dissolving Making Packing Machine

$45999.00

Product Profiles

The oral dissolving film production machine is used to manufacture film products that can quickly dissolve in the mouth. Its working process is precise and efficient first, the material is mixed with the film-forming material and solvent in a specific proportion, and then stirred and heated to form a uniform coating solution. Then, the coating system, the coating solution is evenly coated on the release film substrate, and the film thickness and uniformity are precisely controlled. Subsequently, the coated film sent into the drying room to quickly evaporate the solvent and solidify the film. Finally, the dried oral dissolving film is stripped from the substrate, cut into, round and other shapes according to the product specifications with cutting equipment, and then packaged with aluminum foil bags, plastic bottles, etc., which is convenient for storage transportation and use.

Product Name | Oral Film Dissolving Making Packing Machine |

Packaging Film Material | Heat sealable composite packaging film like easy-peel film Φ≤320mm, width≤400mm |

Production Capacity | 120-160(Bags/Min) |

Noise | ≤75dB |

Film Size | 30*25mm Adjustable |

Bag Making Size | 85*45mm Adiustable |

Power Supply | 220V/380V 50Hz 4.0Kw |

Consumption of Gas | 230m³/h (Self-provided) |

Air Pressure | 0.6-0.8Mpa |

Weight | 800KG |

Dismension | 4000*1300*1600mm |

Packing Dismension | 2200*1900*1800mm |

After-Sales Service Provided | Provide one year of equipment consumables |

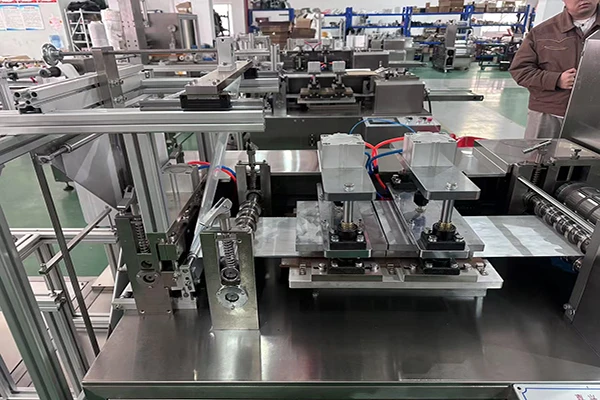

Model Parts

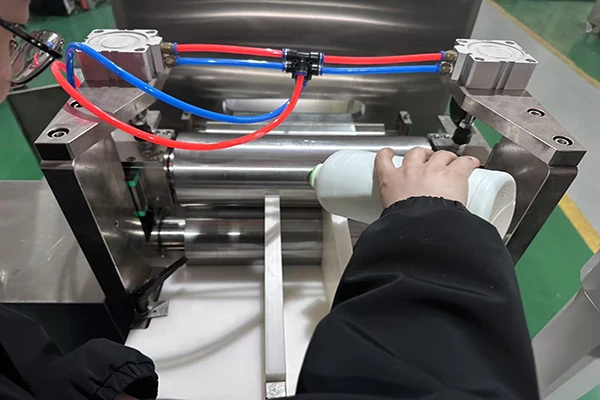

Moulding System

The thickness size and shape of the film can be precisely controlled, ensuring that each oral film has consistent specifications accurate dosage, thus ensuring accuracy stability, which is conducive to the control and standardized production of product quality. In the process of mold making, the molds and processes used can minimize the of materials on the surface of the mold, which is con-venient for the cleaning and reuse of the mold, reducing production costs, avoiding the impact of residual substances the quality of subsequent products.

Process Flow

Oral dissolving film roll on the machine → Longitudinal slitting → Transverse cutting → Direct bagging → Easy-peel film bag making → Sealing packaging bag cutting → Conveying the packaged product

Main Features

1.Unique bag-making mechanism design: can produce packaging bags with text and patterns on both the front and back sides. 2.Unique film loading mechanism design: the film slices after being dissolved in the mouth directly enter the packaging bag, stable and reliable, avoiding the problems that arise during the transfer process. 3.Scientific and stable heat sealing mechanism: continuous, flat pressure heat sealing, reciprocating operation. The heat sealing time is, making the heat sealing effect better; the adaptability of the material and thickness of the packaging is wider. 4.The overall machine design is directly visual, and the mechanical mechanism is clear at a glance: easy maintenance. 5.The machine operation is centrally controlled by PLC programmable controllers and new technology software systems by the factory; the feeding, film pulling, heat sealing operation, and bag cutting all adopt servo drive, with high bag-making accuracy and stable operation. 6.It is equipped with a built-in film longitudinal slitting system, which is divided online.

In the realm of pharmaceutical manufacturing and packaging, the oral film dissolving packaging machine stands out as an essential piece of equipment for delivering innovative drug delivery systems. This machine is designed to handle the production and packaging of oral dissolvable films, which have gained popularity due to their convenience, ease of use, and rapid dissolution characteristics. In this document, we will explore the functionality, qualities, and advantages of the oral film dissolving making packing machine, as well as its impact on the industry. ### What is an Oral Film Dissolving Packing Machine? An oral film dissolving packing machine is a specialized device that produces thin, flexible films made from polymeric materials. These films can carry active pharmaceutical ingredients (APIs) and dissolve quickly upon contact with moisture in the mouth, allowing for fast absorption and onset of action. The process involves several stages, including film casting, drying, cutting, and packaging. ### Key Features of the Machine 1. **Film Production:** The machine typically utilizes a casting system where a liquid formulation is spread over a substrate to create a thin film. The formulation must include the desired ingredients such as polymers, stabilizers, sweeteners, and flavors, ensuring that the final product meets the necessary standards for efficacy and palatability. 2. **Drying and Curing:** After casting, the films must be dried to remove excess moisture. Advanced machines use controlled drying methods, such as infrared or heated air systems, to ensure optimal consistency and avoid degradation of sensitive compounds. 3. **Precision Cutting:** Once the films have dried, the machine cuts them into desired shapes and sizes, which can vary based on the intended dosage and application. Precise cutting reduces waste and ensures uniformity in each dosage form. 4. **Automated Packaging:** After cutting, the films are automatically packaged. The machine may offer options for blister packaging, sachets, or foil wrapping, maintaining integrity and protecting the product from environmental factors such as moisture and light. 5. **User-friendly Interface:** Modern machines often come equipped with intuitive user interfaces that facilitate easy operation, allowing operators to set parameters, monitor the process, and manage quality control efficiently. ### Advantages of Oral Film Technology Oral dissolvable films present numerous benefits for both manufacturers and consumers: - **Convenience:** These films provide a portable and easy-to-use dosage form that eliminates the need for water, which is especially appealing for individuals who may have difficulty swallowing pills. - **Rapid Dissolution and Absorption:** The films dissolve quickly in the mouth, leading to faster absorption of the medication compared to traditional solid dosage forms. - **Taste Masking:** Flavors and sweeteners can be incorporated into the film, improving the taste and compliance for pediatric and elderly patients. - **Targeted Delivery:** The ability to customize the film’s composition allows for targeted delivery of drugs that require specific solubility profiles. ### Applications in the Pharmaceutical Industry Oral film dissolving machines are versatile and can be used for various therapeutic applications, including: - **Pain Management Products:** Fast-acting analgesics can be delivered effectively through oral films. - **Anti-Anxiety Medications:** Films can provide quick relief for patients needing immediate anxiety management. - **Nutraceuticals:** Dietary supplements and vitamins can be formulated into films, capitalizing on the health-conscious market. - **Children’s Medications:** Medicines targeting younger audiences can benefit from the ease of use and improved compliance inherent in oral films. ### Conclusion The oral film dissolving making packing machine represents a revolutionary advancement in the field of pharmaceutical manufacturing. Its ability to produce efficient, convenient, and versatile oral dosage forms is reshaping how medications are delivered to patients. As the demand for innovative drug delivery systems continues to grow, this technology plays a pivotal role in ensuring that pharmaceutical companies can meet the needs of modern healthcare. By investing in high-quality oral film dissolving packing machines, manufacturers can enhance their production capabilities, streamline operations, and ultimately improve patient outcomes.